Our main advantage is all our boxes are supplied using existing tooling, so no tooling costs.

We are the only company in the UK offering such a large and comprehensive range of existing sizes and shapes. We specialise in the smaller sizes, from really tiny ones up to around the size of a large box of chocolates or paper size A4. If the size you want is not on our website, then it probably doesn’t exist.

Though many of the bigger heavy duty plastic containers, trays and shippers are still manufactured here in the UK, sadly the smaller ones like ours are not, so we are forced to import from factories all over the world, to satisfy the demand from a wide variety of markets here in the UK.

We only deal with top quality manufacturers with reliable, long established reputations, for whom quality is paramount.

If we cannot find the size we want, can you make it for us?

Yes, no problem. For customers who require a dedicated box, to their own specific dimensions, we can custom-make it, which would involve creating tooling, for which there would be an extra charge.

Why use Plastic to pack my product?

- Visibility (being transparent, product is immediately visible with enhanced appearance)

- Presentation (shelf appeal, clean and professional look)

- Strength (plastic is stronger than cardboard and more durable).

- Postage Costs (being lightweight, saves money on postage)

- (does not go soggy and fall apart when wet, like cardboard)

- Popular (over 53% of all goods are packed using plastic)

What colours are available?

The bulk of our range is Transparent plastic, but solid or tinted colours are also available.

Can the Boxes be printed?

Yes. The Print options include Silk Screening, Digital Printing, Pad Print and Laser Etching. Holograms are available too.

What shapes are the Plastic Boxes?

- Rectangular

- Square

- Round

- Oval

What about the choice of Lids?

- Hinged

- Lift-Off / Push-Fit

- Sliding

What are your boxes made from?

- Crystal Polystyrene (Glass Clear)

- Polypropylene (less brittle and stronger than Crystal Polystyrene, more cloudy appearance)

- ABS

- Perspex

- Polycarbonate (a lot stronger then Perspex and more expensive)

The choice of Plastic depends on the intended purpose, end-use or market.

How are Plastic Boxes made?

Injection-Moulding is used for producing Polystyrene and Polypropylene boxes.

Perspex and Polycarbonate boxes are hand-made and finished, involving Laser Cutting, CNC machining and hand polishing for a pristine appearance.

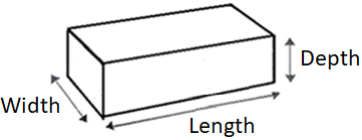

How is a Plastic Box measured?

By Length x Width x Depth as below:

Note: All Dimensions on our website are approximate inside dimensions.

Can Plastic Boxes be recycled?

Since the properties of polystyrene change only slightly, even after repeated processing, it can be recycled very well, though polystyrene is slow to biodegrade. In the sorting plants, hard PS can be easily separated using near-infrared technology. Pure polystyrene is mechanically shredded and processed into high-quality recyclate, which in turn can be remelted into new products, using an injection moulding processes. If plastic is correctly separated after use, old plastic can be turned into new plastic, if processed correctly by being separated, sorted and put through a re-grinding process.

Sustainability

There are different standards worldwide for the collection of used plastics. It is therefore possible that the processed recycled material will exhibit colour differences, depending on the process used or degree of sorting. Country-specific factors also play a role here. Darker material is produced, for example, when plastic waste like yellow sacks are collected for further processing into recycled material.

Post-industrial recyclate is made from leftovers from the plastics industry, such as punching remnants or defective batches. These materials are easy to recycle as they are single-grade and largely uncontaminated. Wherever PCR is not available or a special material purity is required, PIR offers a viable alternative to virgin material.

The starting raw material for the post-consumer recycling consists of packaging waste that has been recycled by the consumer.

Our industry is constantly searching for alternative plastic packaging solutions, that are biodegradable or derived from sustainable sources.

Who uses Plastic Boxes for their Packaging?

Our boxes are used throughout many different sectors. Science and Technology, the Aerospace Industry and the Ministry of Defence, in Healthcare Testing Kits, Surgical instruments and Laboratory Research programmes, Electronics, Dental or Industrial Ceramics. Widely popular with many branches of Universities and Archaeological institutes. Other fields where they are used for Presentation Packs, Marketing Promotions, Gift ware, Hobbies, Travel kits, Sewing Kits, Survival kits, First Aid Kits and Accessory Kits. They are useful for the storage and study insects, butterflies, ants and in the field of geology to store and collate fossils or minerals. The organising and storage of Small Components or Spare Parts, Arts and Crafts. They are useful for displaying/storing collections of Awards and Trophies, Dolls, Model Trains and Cars. Stationery is catered for with A4 and A5 sizes. Where clarity is important, we can offer glass clear transparency. Normally supplied with clear lids and clear bases, some are available with clear lids and coloured bases.